Gain detailed insights into product structure and costs for smarter decision-making.

Optimize manufacturing and purchasing with AI-driven demand forecasting and smart material planning.

Eliminate manual data entry and reduce errors.

Ensure timely availability of materials and components.

Adapt to changing market conditions and customer needs.

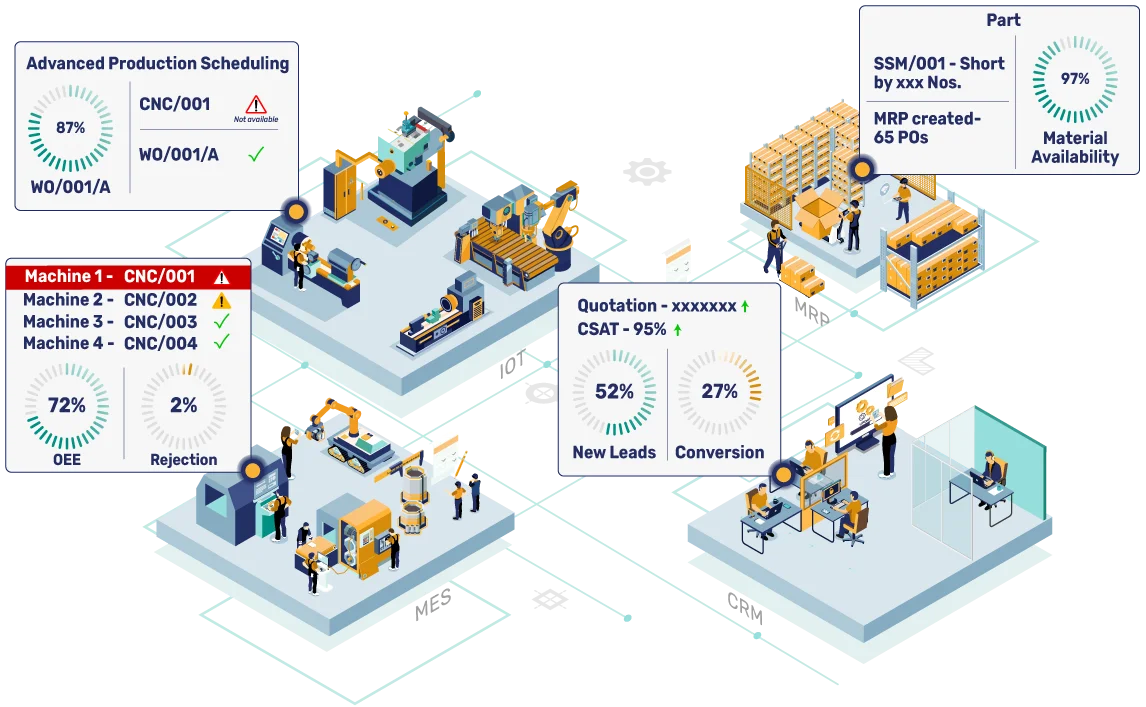

Create precise production schedules based on real-time constraints. Eliminates the infinite capacity planning method.

Minimize manual intervention and eliminate human error

Quickly adapt to changing demands and unforeseen challenges.

Maximize the efficiency of your production resources.

Identify potential issues before they escalate into cost-intensive breakdowns.

Streamline maintenance scheduling and task assignments.

Reduce spare parts costs and ensure timely availability.

Maintain regulatory compliance and industry standards.

Gain valuable insights to improve maintenance performance.

Identify and address quality issues before they impact your products.

Implement effective corrective and preventive actions (CAPA) to prevent recurrence.

Adhere to industry regulations and standards.

Maintain comprehensive and organized quality records for easy traceability.

Leverage analytics to optimize your quality processes.

Track key performance indicators like OEE, production rates, and downtime.

Identify and resolve potential issues before they lead to breakdowns.

Optimize machine utilization and reduce operational costs.

Make informed decisions based on real-time data.

A single source of truth for all your manufacturing data.

Streamlined workflows and reduced manual data entry.

Data-driven insights to optimize operations.

Integrate seamlessly with your existing tools like SolidWorks, Tally, and Zoho Books. Empower your workforce with user-friendly tablets for seamless shop floor data capture. Even run your e-commerce portal powered by PlantMetrics.